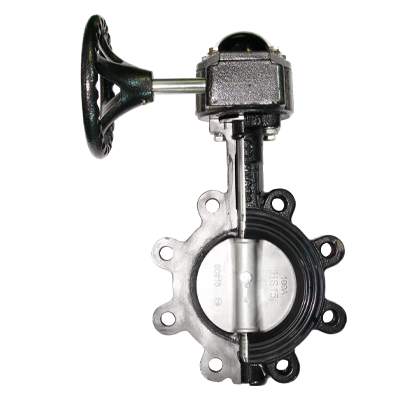

Catridged seat butterfly valve

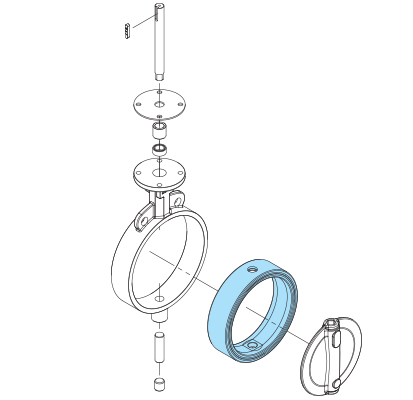

Cartridge Design Seat

Elastomer is supported by hard phenolic backing which eliminates seat shifting during installation.

Seat to disc seal is independent of flange support and capable of full rated dead end service.

Static seat design allows disc to sweep into seat for lower and more consistent torque.

Smaller mass of elastomer minimizes seat swell.

Standard Specifications

-

DESIGN

▪ API 609 Cat.A

▪ ISO 5752 Sr.20

▪ MSS SP 67FACE-TO-FACE

▪ API 609 Cat. A

▪ Wafer and LuggedFLANGE STANDARD

▪ ASME B 16.5

▪ BS 4504 / EN 1092-1

▪ JIS B2220

▪ Others on request -

PRESSURE RATING

▪ 20 Bar

▪ 285 PSINOMINAL DIAMETER

▪ 2” to 24”

▪ DN 50 to 600TESTING

▪ Shell : 31 Bar or 450 PSI

▪ Closure : 23 Bar or 325 PSI

Applicable Materials

| Cast Iron | A126 CL.B |

| Ductile Iron | A395 Gr.60-40-18, A536 Gr.65-45-12 |

| Austenitic Stainless Steel | A351 CF8 / CF8M / CF3 / CF3M |

| Duplex Stainless Steel | A890 4A / 5A / 6A, A995 4A / 5A / 6A |

| Special Alloy | Inconel® 625(UNS N06625), 254SMO®(UNS S31254) Monel® K400 / 500 (UNS N04400 / N05500) |

| Liner | Nitrile Rubber with Phenolic Backing EPDM Rubber with Phenolic Backing |